Master Lock F25 Padlock Lock Picking (and a WB padlock)

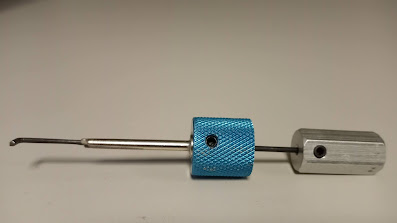

The Master Lock F25 is a warded padlock with a variable height shackle. I did not have the key, and I did not have any warded picks, so for fun I modified a different pick I've never had reason to use.

I bought a $14 two-pick disc detainer lock pick set. One is shaped like a + sign and works great, the second one has a HUGE square end that hasn’t fit into any lock I’ve come across. So, I took the second huge disc detainer pick (not the nice "+" shaped one) and cut the unusable thick "flag" off the end.

Then I

bent the wire tip 90 degrees.

Then I cut the blue

handle down and ground down the silver tube part down. This gave me extra length.

I could have just removed the blue handle part entirely.

This made this

especially to pick/bypass this Masterlock F25 warded lock. The F25 has a

zig-zag keyway and has a wedge thingy that grabs the indent on the inside of

the shackle. There are indents on both sides of the shackle, but only one side

of the lock. This way you can place the removable shackle in either way

left/right. What is bad is that there is only one wedge-shaped locking thing so

it’s much easier to pick than if

there was one on each side!

Looking inside the left shackle hole shows the locking mechanism. The right side is a smooth hole which place no part in locking this lock.

The tolerances on the shackle

are tight. A padlock shim would work—but

there is not enough room to slide one in-between the shackle and the hole it

goes into. You would only need to shim one side of the shackle, but you wouldn’t

know which side. I consider this padlock to be basically shim-proof.

The shackle has multiple indents so you can lock it as tall or short as you want. There are four height levels for the shackle to close down to. That’s actually a pretty nice feature!

How do you pick this

lock?

I used this modified

pick to probe the inside of the lock about halfway down and found the

"clicky" spinning part deep down inside. The shackle isn’t spring

loaded, so you have to balance holding the spring-loaded wedge open without

going to far—and then gently pull the shackle out; or let gravity do it with

the shackle facing the floor if there isn’t too much rust.

If you imagine the

lock with the keyhole facing the sky and looking down inside there are “ledges”

which are the wards. These are non-moving. The second or third one down has the

moving spring loaded release mechanism underneath

it. Poke the pick into the lock and let it rest on the middle ledge (ward).

Carefully move it just underneath so you’re scraping the underside of this

ward. Rotate the pick like a key and push and hold the release mechanism to

free up the shackle. Scary simple once you figure it out!

Yes, it’s pretty easy

with the right tool. In my case I didn’t have any warded lock picks at the time

so I made this pick—for fun! A quicker solution would have been one of those Four-For-Three-Dollars

Harbor Freight pick sets with the orange handles. The one with the 90-degree

bend at the tip probably would have worked just as well. But it might have been

a little too long. When I made me 90-degree bend I made the bent tip about half

the width of the keyhole. That way I knew it would fit inside and be able to

spin.

Luckily, this lock

only has one release mechanism. If it had one on either side I would have

needed a “T” shaped tip instead of a “7” shaped one. In that case an unmodified

disc detainer pick with the square paddle at the end may have worked. Alas,

Master Lock did not build it that

way. Still a nice lock though. But it’s one you can bypass/defeat without even

needing a tension wrench.

I like my solution

better because it was more fun.

The wards are

non-moving obstacles. You can just work above or below them.

They just keep you from being able to jam a popsicle stick or something like

that into the lock and turning it.

However, if you split a popsicle stick in

half lengthwise you can twist it gently but firmly in the lock, you would see where the non-moving wards

leave an indent and then cut slots in those places: boom, now you have a wooden

key for that lock!

Of course, you’d want to transfer that pattern to something

stronger than a popsicle stick, like a stiff piece of plastic or metal. As long

as you spin anything that is the

width of the keyhole (or half it’s with and hold it carefully) without jamming

against a ward it should open the lock.

A quick post script: the demonic WB padlock.

This lock had me beat. It was on my desk for a week. I would fiddle with it on and off in between other projects. The shackle is really long, but also bent. The side of the lock is bulged out a little. I havd no key for it. I figured maybe it was broken?

Then i accidentally put the tension wrench in backwards and tensioned it COUNTER-clockwise. It basically opened right up with almost zero effort! Lefty-loosey-openy!!

I put tension on it and put a simple pick i to the keyway and it turned. Mo effort. Essier to pick than my transparent plastic practice locks.

When all else fails...