I turned a larger, cheap $25 clamp-style 2" knurling tool into a rear mount knurler for my Taig Microlathe 2.

Sunday, September 3, 2023

Taig lathe knurling tool conversion

Wednesday, May 24, 2023

Watchmaking: First Screw Made

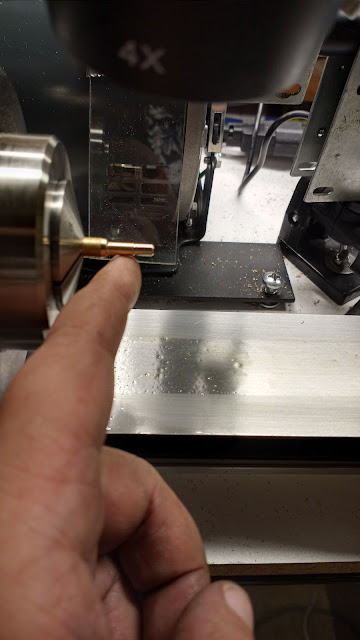

Watchmaking: First Screw Made

Taking a 3mm O1 (cool hardening) steel rod and making a very tiny screw from it. Here is what will be the threaded portion still on the lathe next to the screw die plate I threaded it with.

The plate can thread screws down to 0.7mm up to 2.0mm.

Saturday, October 30, 2021

Watchmaking Machinery Part 1

Watchmaking Machinery Part 1

The initial order to Taig was for:

1017#3 Starter Set #3 - Base + 5C Headstock

1096 Unground tool bit 1/4" square

1170 Extra Tool Post 6

1171 Back Tool Post 2

1110 Slitting saw arbor

1232 1/4" Diameter Milling Cutter

1230A 1/16 dia Milling Cutter

1230C 1/8 dia.Milling Cutter

1111 Hi Speed Slitting Saw

1152 Die Holder for Tailstock

1224 Fly Cutter

1210 Radius Turner

1038 4 inch swivel joint tool rest (wood turners)

1190 Steady Rest

1225 Milling Vice

1173 T Bar Cutoff Tool

1200 Top Slide Mounts 1220

Milling attachment

300-82 (T-Bar Cutoff Mount)

Tons of other tools, bits, bit steel to grind my own cutters, calipers, dial indicators, raw metal stock, etc. are on their way too.

The first learning goal is to take an existing watch movement and replace it piece-by-piece with pieces that I manufacture. Replacing steel with brass, until I've made a complete movement. See you in a few years...

The chosen movement is an ETA 6498 M03 that was introduced in 1950. It's a pocket watch movement. ETA's website is awful and always down for service. If you need the tech specs for this movement do a search for "'CT_6498-2_FDE_482480_08" and there will be a few results.