So, making wristwatch parts requires teeny-tiny little drill bits (0.3mm). For fun I took my mini cylindrical drill, a drill press stand and a magnifying LED light with clamp and made my own micro precision drill press.

I shopped around: a USED micro drill press is close to $8000. A crappy one is $350. This cast iron beast was way, way, way less than all that.

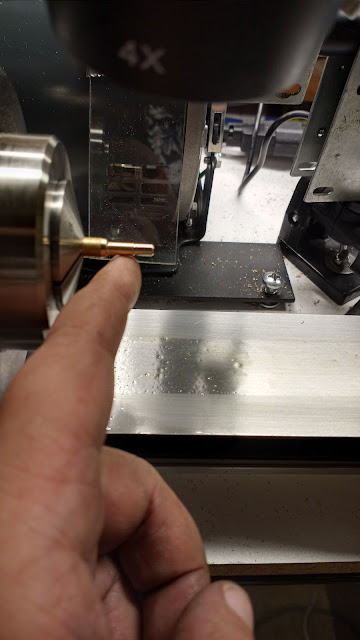

Feast your beady little eyes on my sub-millimeter hole shooter (explanations after the photos):

This stand is fantastic. I added a "micro drill" to it instead of a corded drill. This is for micro drilling. I'm using drill bits with diameters of LESS than a millimeter usually. Watchmaking 0.3mm to 2.4mm bits usually. Some of them are literally thinner than a human hair. Most people buy these for CORDED drills with clamping collars (i.e., most corded Milwaukee, Metabo and Wen drills).

This stand is VERY heavy for its size due to its cast iron base (I checked it with a magnet). The magnet stuck to all the green parts. The magnet did NOT stick to the yellow part (the moving dovetail part of the head and the drill collar clamp part). The magnet also stuck to the actual column, meaning it's steel and not aluminum. The rotating part of the head is green and steel. I'm not using that function, but it's still nice.

The jibs (part that the dovetails rub against) are replaceable copper strips. The dovetail tightness can be adjusted by screws. Yes, you can fine tune this thing just like a lathe or milling machine. That simple thing is a HEAVY DUTY feature in any machine.

The spring is fairly hard to pull down without a drill in it. I'm assuming once you put a heavy corded drill in there it will pull down easily. My cylindrical drill is very light comparatively--so there is a little extra pressure needed. Although it's not bad. If it was a problem you just unhook the bottom of the spring, and pull it up out the top and replace it with a weaker (or stronger) spring to suit your taste. I'm just happy that the flat pinion rack (flat part of metal that engages with the gear when you pull the lever down) is nice and smooth. VERY smooth.

Here's a tip: if you don't want to bolt this to a bench top you can bolt three rectangular blocks of wood to the underside of the base. The left/right support the press on a table/shelf for storage. Then when you want to use this thing you clamp the center block of wood into a vise. I have that on some mini-vises that can clamp into bigger vises like Ukrainian nesting dolls. LOL! Anyway, YOU NEED TO CLAMP/BOLT/SCREW this to a work surface--it's not super tippy, but when you pull down on the lever it will be. The base has holes in tabs in all four corners (plus one huge hole in center).

When open the circular hole that you clamp on your drill collar is 43mm. My cylindrical drill has a diameter of 40mm. I needed one of the (three or four) plastic sleeves they give you to assist clamping smaller collars. That 3mm thick sleeve really made a difference.

In my photos I show a 1mm drill bit in my drill--but shown through the magnifying lamp I added. My intention is to add a wooden base with a couple drawers for tiny drill bits--and then mount the speed control for my drill (0-13,000 RPM) to the LEFT side of the cabinet. That way I can adjust the drill speed with my left hand while pulling down with my right.

Things I would change:

It comes with FOUR Allen key/wrenches because they used FOUR different sized Allen bolts. One of the keys only fits the bolt for the arrow pointer head thingy on the depth gauge. It doesn't matter to me, but they'd have to buy/store/track 1 less bolt size, 1 less nut size, and give away 1 less Allen key if they just settled on THREE sizes of bolts. They could probably just use TWO sizes.

The depth gauge has "6" at the top and "0" at the bottom. That means as you pull down on the drill your depth gauge is reading backwards. A two centimeter deep drilling hole goes from 6 to 4--instead of 0 to 2. I've seen that on other tools, and it's annoying.

The cap on the top of the column has a little hook for the drill power cord. It's very open and the cord can fall out. No big deal, it's probably loose so the cord doesn't catch and the drill moves down--but maybe a "V" shape that contains the cord and let's it move rather than a "C" shape that lets it fall out. With that said, my drill cord and my magnifying light cord seem pretty happy--and I can always zip-tie them loosely if need be.

Why did I do this when I have other BIG drill presses, lathe, etc.? I'm playing around with a couple of wristwatch movements and wanted to drill REALLY small holes. I started looking at tiny drill presses: garbage plasticy ones for $80; garbage plastically ones for $350; nice ones at about $1000. Really nice ones up to $15,000. Yes, the price of a car--for a teeny tiny drill press. Look up used "Precision drill press" and you'll be amazed. No thanks.

There is a somewhat similar drilling stand which looks cooler (all steel) but it looks like it has rack and pinion metal-strips pop riveted together as it's movement mechanism. Lots of sideways jiggle and non-repeatable drilling (can't hit the same hole twice). No thanks.

To be clear: the magnifying light and cylinder micro drill DO NOT COME WITH THIS THING.

Anyway, I would go this route versus a sub-$1000 precision drill press. Anything under $1000 is going to be trash. Make your own setup with this.

M1K3 FR0M D3TR01T